This is Part 4 of our series “Our View: Looking Back At 2020.” If you missed previous parts in this series, you can read the summaries below and find links to the posts in their entirety.

Part 1 Summary

Our fairly new company had a lot of consulting and training work booked in the first quarter of the year and we were very optimistic. And then, while out on the road, the world changed as the pandemic took hold. (To read Part 1 in its entirety, click here.)

Part 2 Summary

To get the work done, we had to change all of our travel plans and logistics. We worked with our client to make sure we left them with good printing conditions. Then, we began the long – and eerie – voyage home. (To read Part 2 in its entirety, click here.)

Part 3 Summary

To offset some of the revenue we were losing, we launched The Jim & Shelby Show. But it just wasn’t enough. We were on the brink of layoffs when we had our epiphany. We called on our partners in the industry for help and soon we launched a dye sub business making socks and gaiter style face coverings. (To read Part 3 in its entirety, click here.)

Part 4: The New Venture

Jim and I are not strangers when it comes to entrepreneurship and starting up businesses. People have great ideas all the time but then don’t act on them. Jim and I don’t mind taking calculated risks and we aren’t afraid to try something new. And when we start a new venture, we tend to do it pretty fast.

We had the order for 1,000 gaiters to get us started; but a new business needs more than one order. We needed a strategy for an online presence, how to handle production and shipping, marketing and hundreds of other details.

Since I have a graphic design background, it made sense that I would be the one creating our custom designs for our products. But it wouldn’t be very efficient for me to create digital designs in North Carolina while the physical prototypes would be produced in Wisconsin.

One of the bigger and better decisions we made early on was that we needed to set up a second dye sub lab in the spare bedroom of my house. It was thought at this time that I would primarily be designing and prototyping in my lab and the actual production work would be done in Wisconsin.

Getting it – and us – together

A lot of things would need to happen to get a second dye sub lab ready. Some of the equipment, inventory and supplies were already in Jim’s basement. Others would have to be ordered. I hadn’t been involved in any of the production yet; so I had a lot to learn.

There seemed to be only one thing to do. After 45 days off the road, I was going to have to fly the friendly skies to Milwaukee. Jim would have whatever equipment and supplies he didn’t have that I needed delivered to his house. I would spend a week there learning about production, making custom designs and helping to launch the business.

Then we would load up his SUV with all the supplies and drive to my house in North Carolina. There, Jim would help me set up the lab and make sure everything was working properly.

On May 7, I flew to Milwaukee with a stop in Atlanta. Those first flights and trips through airports were strange and nerve-wracking. Mask requirements were already in place but still not much was known about transmission. Jim had sent me a few gaiters as samples so I used them for my travel. I had read that Delta was boarding back to front so I splurged on a first-class seat. I figured I’d board last and get off the plane first. I made sure my layover was brief and luckily my connection was just one gate away from my arrival gate. I kept my mask on the entire time. I didn’t eat or drink. I only went to my gate areas at the airports and never left – not even to visit the restroom. And I was glad that we were driving back and not flying.

ChromApparel is born.

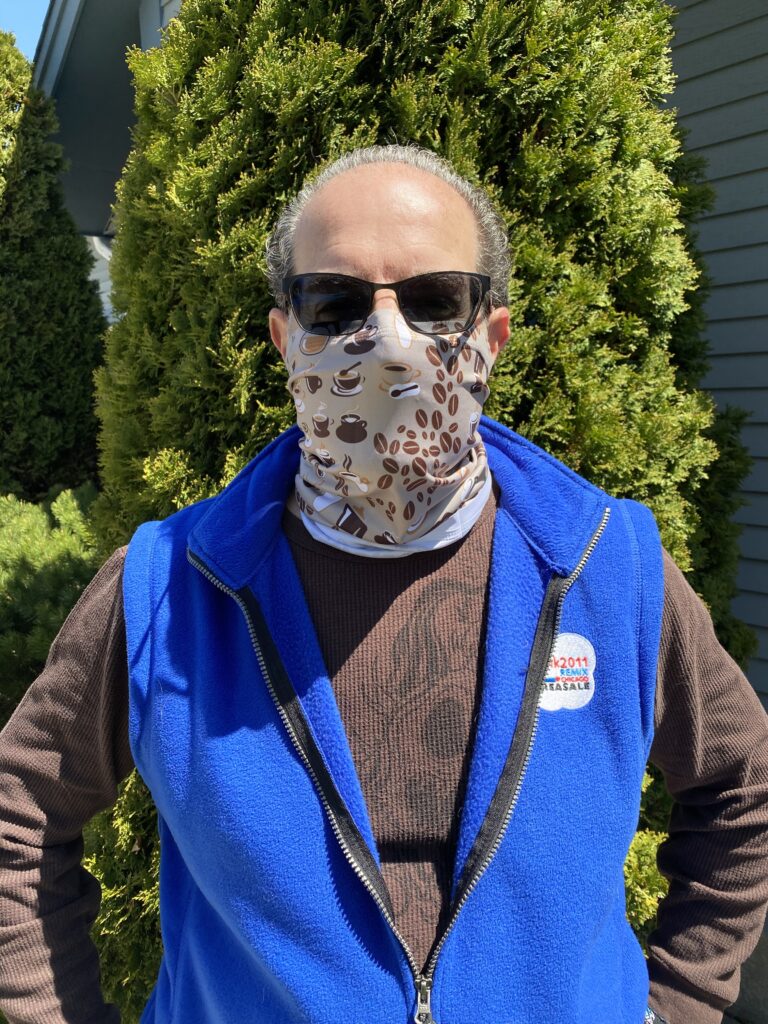

That week in Milwaukee is a blur. From morning to night, we worked tirelessly on our new venture. I learned about the different substrates and paper we were using. I figured out how a heat press works. We subscribed to a stock art library and I cranked out dozens of designs for socks and gaiters so that we would have some initial inventory in our store. We didn’t have a light booth for taking product photos so we were modeling the products ourselves in Jim’s front yard.

We came up with the name ChromApparel (a play on the color term of “chroma“) and Jim bought the domain. In just a few days’ time, ChromApparel.com was live, products were added and the store was working. I launched accounts for the brand on Facebook, Twitter and Instagram.

We started spreading the word on our own networks. Soon, we were getting requests for different designs; i.e. construction trucks, frogs, alligators, sunflowers, etc. I kept a running list of requests and it still exists to this day.

Then it was time to go. One of our employees would finish up the order for 1,000 gaiters. We loaded up the truck and made the 13-hour drive to North Carolina. Again, we took many precautions. We packed a cooler with all the food and drink we would need for the trip. So the only stops were for gas and to use the restroom.

The new lab and another store

There’s plenty of time for discussion during a 13-hour drive. There were some logistics to sort out. We talked about which room in my house should become the lab. I have two spare bedrooms and either could have been the lab. We had to consider power, layout and lighting. Plus, I would need a couple of work tables and better wifi.

Another important discussion we had was about whether we should have a second store on an already established site. We definitely wanted our own domain; but we knew it would take awhile for it to get enough traffic to garner some sales. We also wanted to test the waters and see if our products were in demand. We considered both Amazon and Etsy. In the end, we chose Etsy because Jim already had an account and it seemed more like the style of store where our products could be popular and not get lost in the shuffle.

That week was another blur. There was so much to do. First, we had to settle on the lab’s location. The third bedroom that I was already using as an office was the one we chose. It had a better layout and better lighting. Then we had to get the work tables and everything else we would need to set it up properly. There was testing to be done and inventory to sort. And in between all that, we launched our Etsy store. We decided as a company that I would manage the Etsy store; including production and shipping.

Finally, everything was in place. We had a second working dye sub lab and two stores to manage. Jim got back into his truck and started the 13-our trek back home.

Meanwhile, I researched the Etsy platform and created more products for the store. I amped up the marketing and started a Mailchimp account for ChromApparel.

The summer would be slow for our new ChromApparel/Etsy business. But the summer months also brought new surprises.

Tune in to Part 5 to find out what happens next.

New Podcast!

New Podcast!

Listen to Jim and Shelby discuss this process in the first episode of the DyeSubCast.

Leave a Reply