Life has changed quite a bit in the past month for everyone – both personally and professionally in most cases. Children no longer go to school, we can’t dine at a restaurant and sporting events have been cancelled. Many of us have been furloughed or laid off from our jobs. Some of us are lucky and to some extent can work from home. But hardly anything can be considered “normal” at this moment.

Essential vs. Non-Essential

Due to circumstances beyond our control, our work force has been forcibly lumped into two categories: essential and non-essential. Some jobs, like those of doctors and nurses, are obvious to deem essential. Others aren’t quite so obvious.

But what about us? What about us in the printing industry? Are we essential?

In some cases, we definitely are. An example that quickly comes to mind is a print facility that creates packaging for grocery items. In most areas, the grocery store is the one place we can freely visit. And even in the areas where the rules are stricter, people are still buying packaged items online for delivery to their homes.

For other purpose printers, it might not be so obvious about whether or not they are essential. But we know that in this industry, we are used to change and to adapting to that change. Usually, it’s a change in technology that guides adaptation. While this situation is undeniably something we haven’t had to deal with before, it’s been amazing to watch the many print providers’ responses to it.

By nature, printers are great innovators. Sometimes it seems like every day there is something new in the industry to learn about: new machines, new software, new media, new ink, new ideas. So it shouldn’t be surprising how printers throughout the industry have pivoted from their typical products and services to create new products and services to help their communities during these trying times.

By doing so, they haven’t just made themselves relevant. They’ve made themselves essential. And don’t forget that by doing so, they’ve also been able to keep their employees working.

Since we have been seeing so much awesomeness within our print community, we decided to start featuring companies and individuals who have stepped up, pivoted and innovated themselves into proving how essential print really is.

Our first featured company is Olympus Group, which is headquartered in Milwaukee, Wis.

Olympus Group Pivots To Shield- and Mask-Making

When you think about the products and services that Olympus Group usually provides, you’d probably expect them to have close to no business orders right now.

When you think about the products and services that Olympus Group usually provides, you’d probably expect them to have close to no business orders right now.

Their primary business is creating banners and signage as well as mascot uniforms for sporting events and trade shows. With entire sports seasons cancelled and trade shows either cancelled or postponed like ISA Expo, it’s reasonable to believe Olympus Group would be down to a skeleton staff right now. That couldn’t be further from the truth.

We first heard about Olympus Group’s efforts on LinkedIn. About three weeks ago, President Brian Adam posted that Olympus Group had the ability to cut and sew fabric for masks.

Brian was kind enough to agree to talk to us via a Zoom meeting last week so that he could tell us Olympus Group’s story.

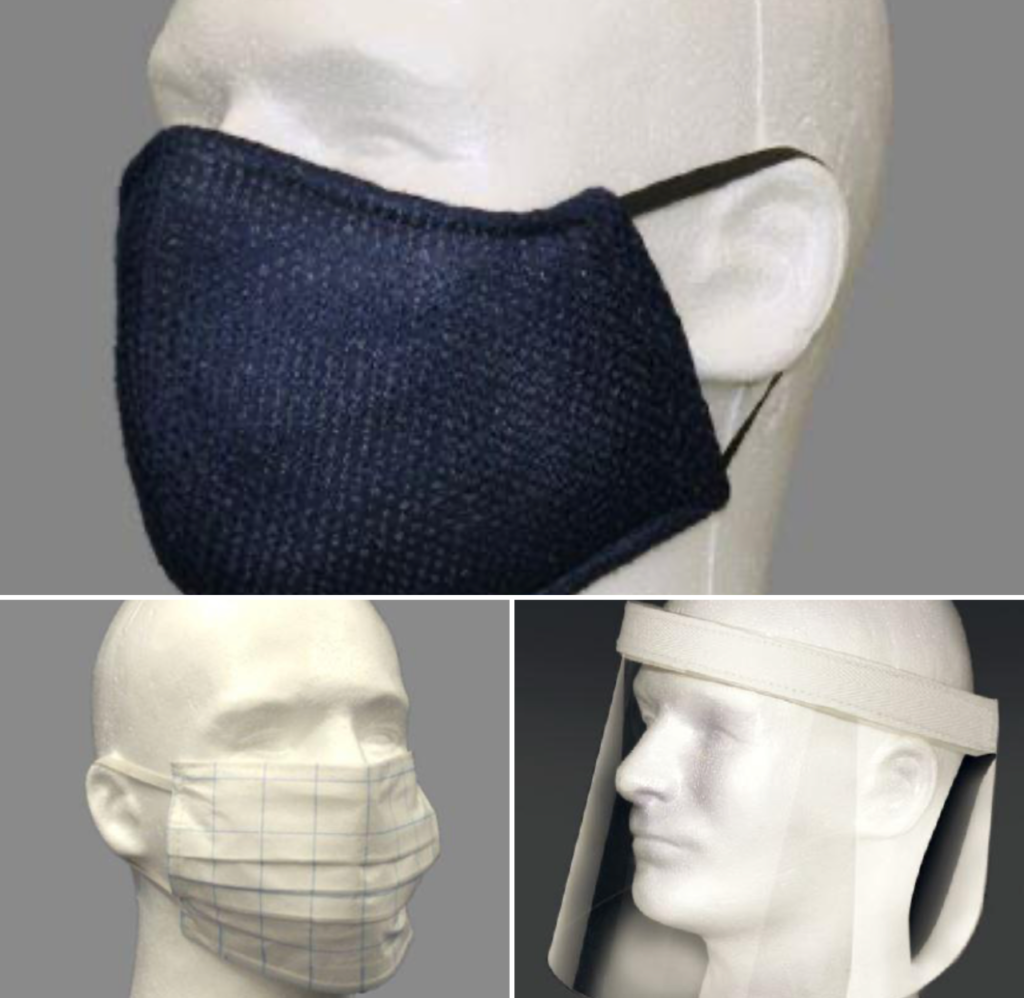

After his initial LinkedIn post, his team created a few cloth face mask and face shield prototypes. Then a meeting was set up with Froedtert, a Milwaukee-area hospital system. They talked with their infectious disease experts to gain an understanding of what the design of the face shield should be. That meeting occurred on a Friday.

By Saturday, Froedtert had placed an order and, by Monday, Olympus delivered thousands of face masks to area hospitals.

Olympus Group’s pivot from “mascots to masks,” which was part of the headline of an April 5th video spot by local Milwaukee TV station WISN, happened just that quickly.

Since then, they are now making disposable face masks in addition to the face shields. While Olympus Group’s Milwaukee location is churning out about 3,000 shields a day, the company’s Orlando location is manufacturing about 100,000 face masks for distribution. These disposable, washable masks can be ordered with stock material or have a customized print.

Because of these efforts, Brian said that Olympus Group has not had to lay off a single employee. While the cost of manufacturing the face masks and shields isn’t offset by the price point, the small revenue coming in from them in addition to the government’s SBA loans should keep Olympus Group’s doors open for another six to nine months.

“We thought: ‘Oh my gosh, all our traditional markets – trade shows, events, amusement parks – all of those are completely gone.’,” Brian said. “We went from thinking we would have to close our doors for two to three months to actually bringing in people from friends’ businesses where they had been laid off – like seamstresses.”

He said Olympus Group has tried to be very transparent with its employees from the beginning. He said that they told their employees about a month ago that their first goal was to preserve jobs and their second was to preserve cash so that Olympus Group can keep existing in the future.

“Then we added a third goal, which was to do good,” Brian said. “Once we started getting into PPE (personal protective equipment), now we know we want to preserve jobs and preserve cash, but we also want to help the hospitals and some other friends of mine.”

Brian told us that the Milwaukee location is now on pace to hit their internal goal of producing 300,000 face shields by the end of May.

“I’m extremely proud of my team,” Brian said.

If you would like to inquire about Olympus Group’s face shields and masks, email them at ogsupply@olympusgrp.com.

Where Do We Go From Here?

Olympus Group certainly isn’t the only company that has made some significant changes to its business to “do good” during this crisis. We have already identified several companies that we’d like to reach out to for an interview.

If you or someone you know has pivoted their business because of the pandemic and would like to be featured in an upcoming blog post, please email me at shelby@colorcasters.com.

And if you have the ability to create 3D prints, here’s a how-to guide I found that I want to share called “Make the Masks.”

To all of you doing good out there, thanks for representing our industry of print in the highest way.

Wonderful story!

A wonderful story about a local company that was quick to respond in a crisis to save the company and to make a difference with one stroke of the brush. Kudos to the Olympus Group.