Note: This post is part of the Color Conversations series. In the series, we post an article pertaining to color. Then we hold a webinar related to the topic. The next webinar will be held at noon CST on Wednesday, Aug. 19. We would like to thank our partner Sun Chemical for their assistance in the production and promotion of the upcoming webinar. Please click here to register. Space is limited.

Note: This post is part of the Color Conversations series. In the series, we post an article pertaining to color. Then we hold a webinar related to the topic. The next webinar will be held at noon CST on Wednesday, Aug. 19. We would like to thank our partner Sun Chemical for their assistance in the production and promotion of the upcoming webinar. Please click here to register. Space is limited.

In the printing world, the topic of color management has been a lively discussion over the years. New theories have been born. New software and equipment have been introduced. But the debate still seems to exist.

In the printing world, the topic of color management has been a lively discussion over the years. New theories have been born. New software and equipment have been introduced. But the debate still seems to exist.

What’s the best printer out there for color reproduction? What’s the best printing environment? What’s the best ink or substrate?

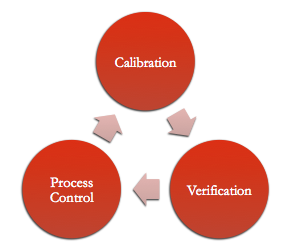

The truth is that the debate doesn’t need to happen. If a proper process control method is used with accurate and consistent color calibration and color verification, then the best technology for the application can be used to produce the print.

Color calibration vs. color verification

The purpose of color calibration is to adjust a printer’s color output to a known state utilizing a gray balance methodology.

Color verification is the use of instruments to measure printed color to ensure that the printer is staying in line with the preferred calibration or profile. When there is a shift in the printer’s output, the existing calibration can be tweaked to return the printer to the same know state thus resulting in repeatable print quality.

When used together, process control is achieved and consistent quality color is produced.

What you’ll learn in the webinar

- The importance of color calibration and color verification and why it’s a cyclical process

- Why instrumentation and color measurement matters

- How process control really works and how we can predict color

- What you gain from using color calibration and color verification

Sun Chemical, a member of the DIC group, is the world’s largest producer of printing inks and pigments. For more information, please contact naimarketing@sunchemical.com or visit www.sunchemical.com.

Leave a Reply