Description

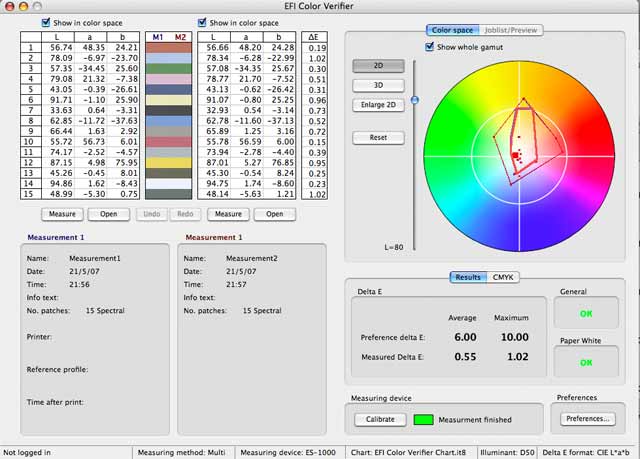

The EFI™ Fiery® Color Verifier Option is an easy to use solution for the control and verification of your color prints. It can measure, compare, verify, and correct color values — producing predicable and reliable printed results.

Verify your color results

Color Verifier makes evaluating color easy. You can compare prints to standards, prints to other prints, profiles to other profiles — or any combination thereof. Therefore providing verified results, quality control, color space and process analysis, and much more. Color Verifier can also correct color based on the delta between the measured and target values, delivering the fastest most accurate optimized results. Color Verifier is compatible with a wide range of the latest external, and built-in spectrophotometers.

Work to industry, or your own standards

Supporting the latest print standards and control strips, this indispensable tool means you can keep up with the latest needs of your industry, and your clients. In-house specifications, and customizable tolerances allow job-specific quality assurance for even the most non-standard color print applications. Individual presets and criteria can be set for any standard, and even specified as normative or informative, providing maximum flexibility to suit your environment.

Make remote color-control easy

The Color Verifier Option is an essential tool for the remote verification of prints too. Together with Fiery XF’s integrated remote verification technology, you can easily set up a remote “proofing” environment. A remote job is created on the senders site, including all relevant information, such as the reference profile, spot colors, and color measurement values, and is passed onto the remote site in a data container. The remote job is output, measured, and verified for color accuracy at the recipient location using Color Verifier. Meaning you eliminate the time-consuming and costly dispatch of physical prints for color evaluation.

Features

- Measurement-based verification tool to check

- Proofs in accordance with industry standards defined in ISO 12647-7 / 8 for contract proofing and validation printing and G7

- Color consistency of proofs, prints and profiles

- Measurement-based comparison of profile-to-proof, proof-to-proof, proof-to-print, print-to-print, profile-to-print or profile-to-profile

- Presets for latest industry standards (ISO 12647-7/8 and G7), certification programs (e.g. FograCert) or Fogra Process Standard Digital (PSD)

- Individual presets definable to update existing standards or adding individual standards

- Criteria and tolerances individually definable and specifiable whether or not they are normative and informative• Support of Fogra media wedge v3.0 and IDEAlliance ISO 12647-7 2013 Color Control Strip

- Support of the EFI Dynamic Wedge™

- Support of two control strips per job or nest

- Printable, extensive ISO compliant report for analysis purposes

- ISO compliant summary for daily proof production, printable on label (supporting DYMO LabelWriter Series 450 and 450 Turbo) or laser

- Support of latest characterization data for ISO and G7 compliant verification• Multi- or single spot measuring• Measuring value display in L*a*b*, LCH, XYZ, RGB or density values in CMYK

- Type of norm light (D50, D65 or C) definable

- Two-way exchange of the measured results via JDF between sender and recipient

- 2D and 3D visualisation of color gamuts

- Out-of-gamut checking for spot colors

- Export of measurement readings via clipboard